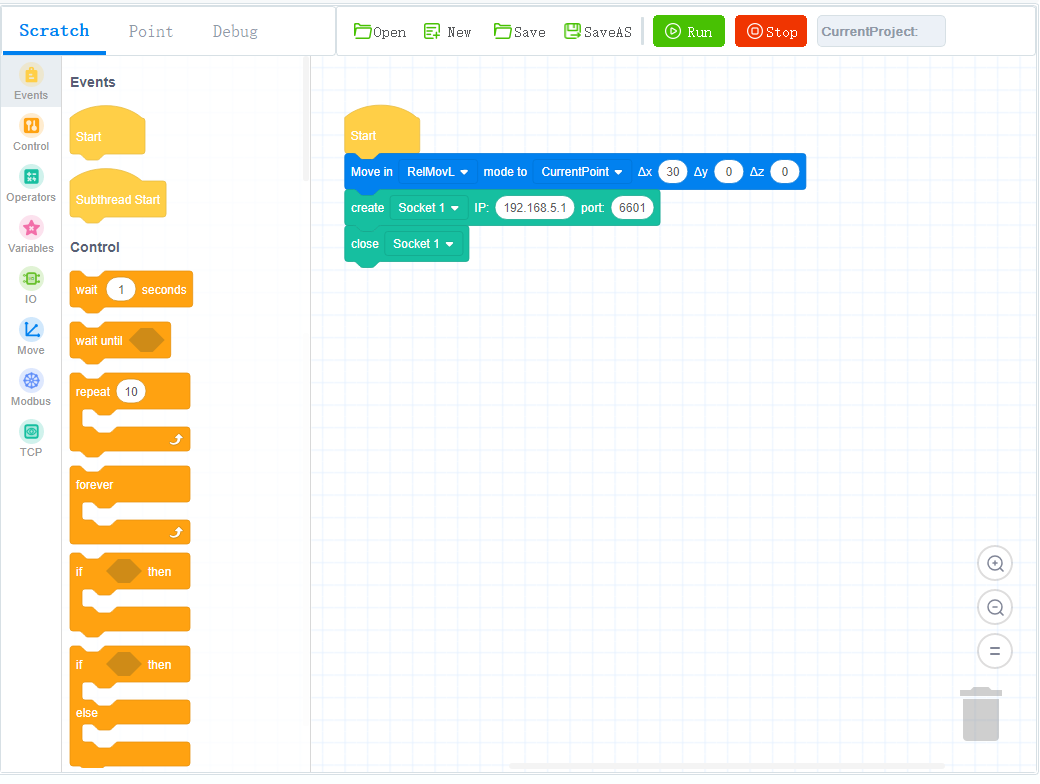

Blockly

The Blockly section of DobotSCStudio allows you to quickly and conveniently program your robot using the Blockly/Scratch block-based visual programming language.

Prerequisites:

- The robot has been powered on

Procedure:

- Press the page with the plus icon to start a new project.

- Drag the blocks to the code area to start programming.

- Set the corresponding parameters of each block according to actual needs. For the description of blocks, please refer to Blockly User Manual (CR Robot).

- In the point page, you can save teaching point that can be called when writing a program.

- Save the project, naming it if saving for the first time.

- Enable the robot arm.

Blockly Commands

Motion Commands

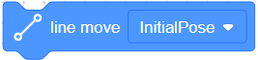

Line Move

Description: Move from the current position to a target position in straight line mode

Parameters:

TargetPoint- Indicate target point, which is obtained from the TeachPoint page

Returns: None

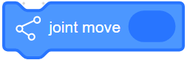

Joint Move

Description: Move from the current position to a target position in point to point mode

Parameters: Indicate the joint angle of the target position, the joint angles is set by Joint data command,

Returns: None

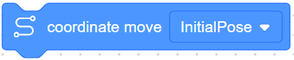

Coordinate Move

Description: Move from the current position to a target position in point to point mode

Parameters:

TargetPoint- Indicate target point, which is obtained from the TeachPoint page

Returns: None

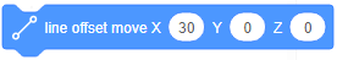

Line Offset Move

Description: Move the corresponding offset in X, Y and Z directions from the current position in straight line mode

Parameters:

X- Indicate offset of X axisY- Indicate offset of Y axisZ- Indicate offset of Z axis

Returns: None

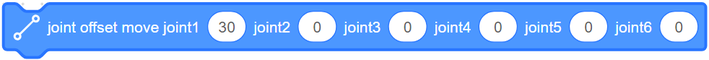

Joint Offset Move

Description: Move the joint offset in each axis from the current position in the Joint coordinate system

Parameters:

joint 1 - joint 6- Indicate angular offset of J1 - J6 axes

Returns: None

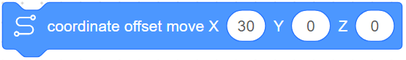

Coordinate Offset Move

Description: Move the joint offset in each axis from the current position in point to point mode

Parameters:

X- Indicate coordinate offset of the X axisY- Indicate coordinate offset of the Y axisZ- Indicate coordinate offset of the Z axis

Returns: None

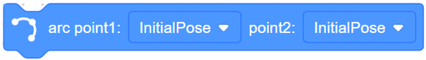

Arc

Description: Move from the current position to a target position in an arc interpolated mode

Parameters:

point1- Indicate the arc’s middle point, obtained from the TeachPoint pagepoint2- Indicate the arc’s end point, obtained from the TeachPoint page

Returns: None

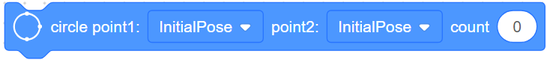

Circle

Description: Move from the current position to a target position in a circular interpolated mode

Parameters:

point1- Indicate the circle’s middle point, obtained from the TeachPoint pagepoint2- Indicate the circle’s end point, obtained from the TeachPoint pagecount- number of whole circles, value range: 1 - 999

Returns: None

Joint Data

Description: Set the joint angle

Parameters:

joint 1 - joint 6- Indicate joint angle of J1 - J6 axes

Returns: None

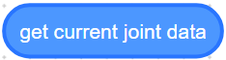

Get Current Joint Data

Description: Get the current position of the robot joints

Parameters: None

Returns: Joint angle of J1 - J6 axes

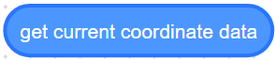

Get Current Coordinate Data

Description: Get the current pose of the robot

Parameters: None

Returns: Cartesian coordinates of the current pose

I/O Commands

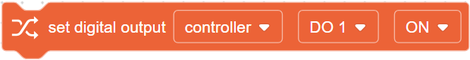

Set Digital Output

Description: Set the status of a digital output port

Parameters:

Control end- controller or toolDO- Digital output index. When you select controller, the value range is DO1 - DO16; when you select tool, the value range is DO1 - DO2Status- set the DO to on or off

Returns: None

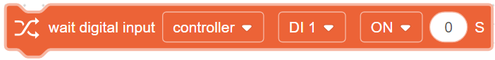

Wait Digital Input

Description: If any of the following conditions are met, the program continues to execute: - The status of DI is the same as the status set by the instruction - The status of DI is different from the state set by the instruction, while the waiting time exceeds the preset time

Parameters:

Control end- controller or toolDI- digital input index. When you select controller, the value range is DI1 - DI32; when you select tool, the value range is DI1 - DI2Status- Indicate status of DITime- Set the waiting time, if the waiting time value is 0, it will wait until the condition is met

Returns:

Set Analog Output

Description: Set the value of analog output port

Parameters:

Port- analog output indexParameters- the value of the analog output

Returns: None

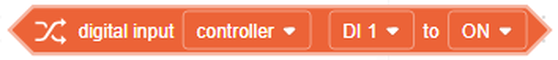

Digital Input

Description: Get the current I/O status, can be used as a conditional in certain instructions

Parameters:

Control end- controller or toolDI- digital input index. When you select controller, the value range is DI1 - DI32; when you select tool, the value range is DI1 - DI2Status- indicate status of DITime- set the waiting time, if the waiting time value is 0, it will wait forever until the condition is met

Returns: Whether the condition is True or False

Get Analog Input

Description: Get the value of analog input port

Parameters:

Control end- controller or toolDI- analog input index

Returns: value of analog input port

Modbus Commands

Get Input Register Address

Description: Read the input register value with the specified data type from the Modbus slave

Parameters:

Address- Starting address of the input registers. Value range: 0 - 4095type- Data typeEmpty- Read 16-bit unsigned integer (two bytes, occupy one register)“U16”- Read 16-bit unsigned integer (two bytes, occupy one register)“U32”- Read 32-bit unsigned integer (four bytes, occupy two registers)“F32”- Read 32-bit single-precision floating-point number (four bytes, occupy two registers)“F64”- Read 64-bit double-precision floating-point number (eight bytes, occupy four registers)

Returns: input register value

Get Holding Register Address

Description: Read the holding register value from the Modbus slave according to the specified data type

Parameters:

Address- starting address of the holding registers. Value range: 0 - 4095type- Data typeEmpty- Read 16-bit unsigned integer (two bytes, occupy one register)“U16”- Read 16-bit unsigned integer (two bytes, occupy one register)“U32”- Read 32-bit unsigned integer (four bytes, occupy two registers)“F32”- Read 32-bit single-precision floating-point number (four bytes, occupy two registers)“F64”- Read 64-bit double-precision floating-point number (eight bytes, occupy four registers)

Returns: holding register value

Get Discrete Input Register Address

Description: Read the discrete input register value from Modbus slave

Parameters:

Address- starting address of the discrete inputs register. Value range: 0-4095

Returns: discrete input register value

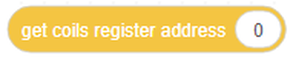

Get Coils Register Address

Description: Read the coil register value from the Modbus slave

Parameters:

Address- starting address of the coils register.. Value range: 0-4095

Returns: coil register value

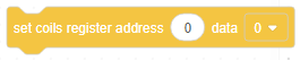

Set Coils Register Address

Description: Set the coil register in the Modbus slave

Parameters:

Address- Starting address of the coils register. Value range: 6 - 4095Value- the value written into the coil register

Returns: None

Note

This command is not supported when the coil register address is from 0 to 5

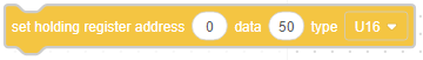

Set Holding Register Address

Description: Set the holding register value in the Modbus slave

Parameters:

Address- Starting address of the holding registers to set. Value range: 0 - 4095type- Data typeEmpty- Read 16-bit unsigned integer (two bytes, occupy one register)“U16”- Set 16-bit unsigned integer (two bytes, occupy one register)“U32”- Set 32-bit unsigned integer (four bytes, occupy two registers)“F32”- Set 32-bit single-precision floating-point number (four bytes, occupy two registers)“F64”- Set 64-bit double-precision floating-point number (eight bytes, occupy four registers)

Returns: None

TCP Commands

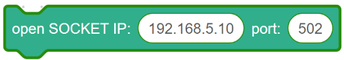

Open Socket

Description: Create a TCP network with the robot as a client

Parameters:

IP- IP address of the serverport- port of the server

Returns: None

Get Open Socket Result

Description: Get the connection result

Parameters: None

Returns:

0- TCP connection is successful1- Input parameters are incorrect2- Socket object is not found3- Timeout setting is incorrect4- If the robot is set as a client, it indicates that the connection is wrong. If the robot is set as a server, it indicates that receiving data is wrong

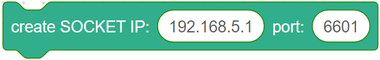

Create Socket

Description: Create a TCP network, robot as a server

Parameters:

IP- address of the serverport- Server port

Returns:

Note

The port cannot be set to 502 and 8080. Otherwise, it will be in conflict with the Modbus default port or the port used in the conveyor tracking application, causing the creation to fail

Get Create Socket Result

Description: Get the connection result

Parameters: None

Returns:

0- TCP network created successfully1- TCP network creation failedSocket- Socket object

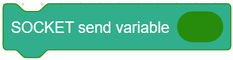

Socket Send Variable

Description: Send data through socket communication

Parameters: Variable: data to be sent

Returns: None

Close Socket

Description: Release a TCP network

Parameters: None

Returns: None

Get Socket Send Result

Description: Get the result of the data communication through the Socket

Parameters: None

Returns:

0- Sending data succeeded1- Sending data failed

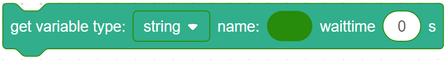

Get Variable

Description: Obtain data through Socket communication

Parameters:

Type- string or numberName- Variable used to hold datawaiting- time: Set the waiting time, if the waiting time value is 0, it will wait forever until data is received

Returns: None

Variables Commands

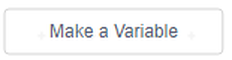

Make a Variable

Description: Make a variable

Parameters:

Variable Name- Name of the variable to be created.

Returns: Defined Variable

Note

You must start with a letter, and you can’t use special characters like spaces in variable names

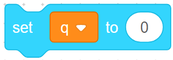

Set Variable

Description: Set the value of a variable

Parameters:

Name- name of the variable to be setparameter- value of a variable

Returns: None

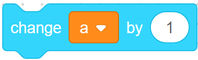

Change Variable

Description: Modify the value of a variable

Parameters:

Name- name of the variable to be changedparameter- The value of an increase or decrease

Returns: None